NORTH AMERICAN INNOVATORS

SPECIALIZING IN GREENHOUSE AUTOMATION

LET’S MOVE

FORWARD

01 // ABOUT US

BORN IN THE ONTARIO GREENBELT.

DESIGNED & BUILT FOR

NORTH AMERICA.

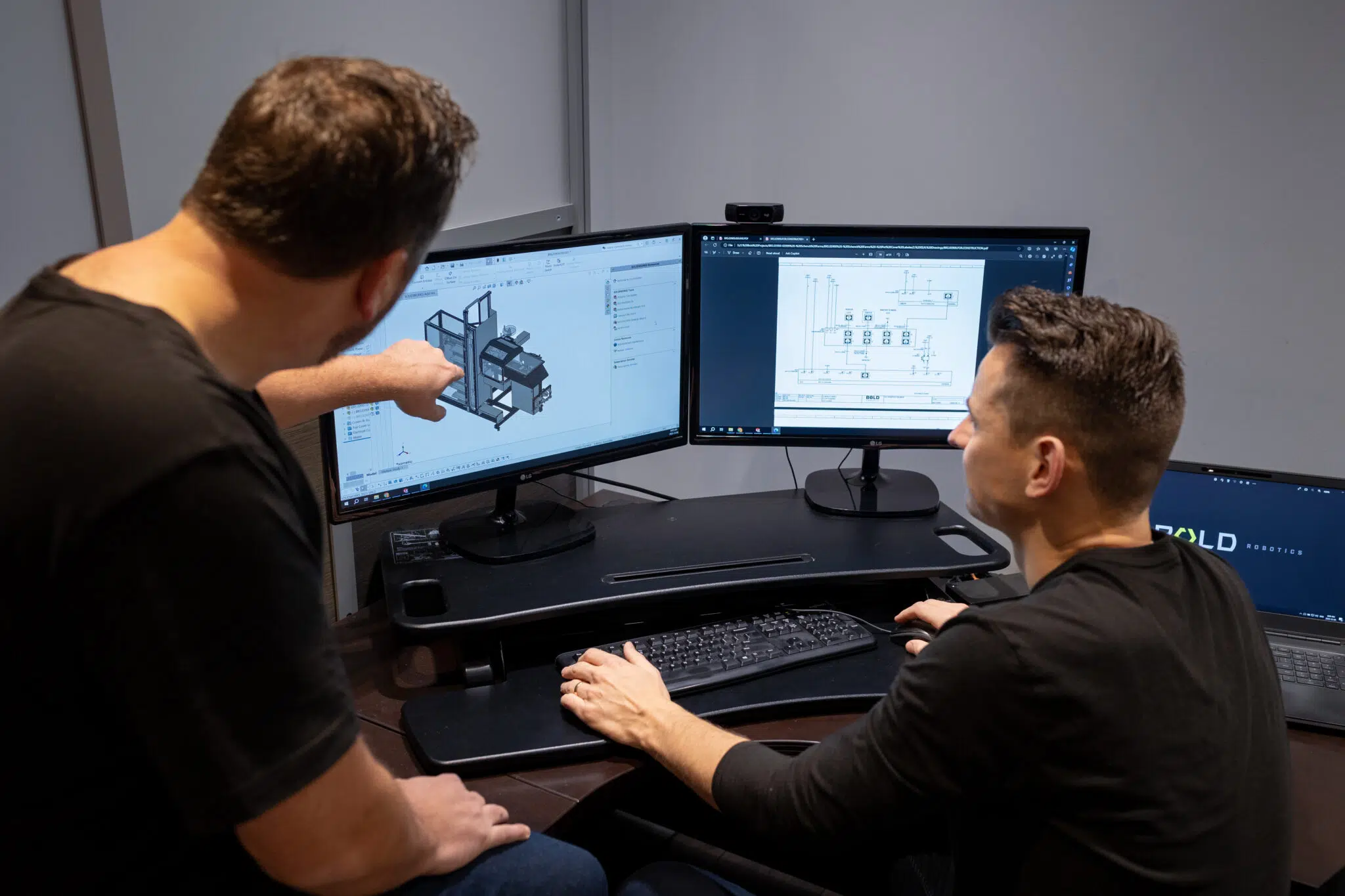

Bold Robotics was founded in the Ontario Greenbelt in 2017 with a sole purpose: to provide top-notch automated equipment for North American growers.

Our focus is providing cost-effective, smart machines that can reduce labour dependencies for greenhouses and nurseries. Our unique background and experience makes us ideally suited to tackle technically complex projects. Our proven approach allows us to successfully implement automation in various industries and market segments.

As we enter 2024 we have added to our focus: to expand and outfit our production line so we can keep up with the demand of our current clientele as well as expand across Canada and into a larger US market.

Our growing and talented team is driven to grow our production capacity with the dream to be an industry leader in both production quality and service. If you have a challenge you think we are the right fit for, or would like to hear more about our vision as a business, don’t hesitate to get in touch.

02 // SERVICES

PRE-BUILT

AUTOMATION PRODUCTS

Over the years, Bold Robotics has developed and patented several state-of-the-art automation machines that have been proven to save operational costs and time. Bold has successfully positioned themselves as a reliable source among greenhouse businesses throughout Ontario. If you are interested in attending a demo please do not hesitate to get in touch with one of our experts.

CUSTOM MACHINE

DESIGN & BUILD

Bold follows a proven process to develop cutting-edge automated equipment for your growing operation. We get to know and understand our client’s process intimately before recommending a custom-tailored solution for your process needs. We study your process, listen carefully to your needs and work diligently to solve your particular operation challenge.

CONTROLS &

SOFTWARE UPGRADES

Do you have older machines that need to be upgraded? Older components become hard to find, and are prone to failure? Our service department is here to help. We have a wealth of experience and can build complete control systems to make your machine run faster and smarter. We aim to respond quickly and offer a high level of service to minimize your downtime and keep your operation running smoothly.

03 // PRE-BUILT

AUTOMATION PRODUCTS

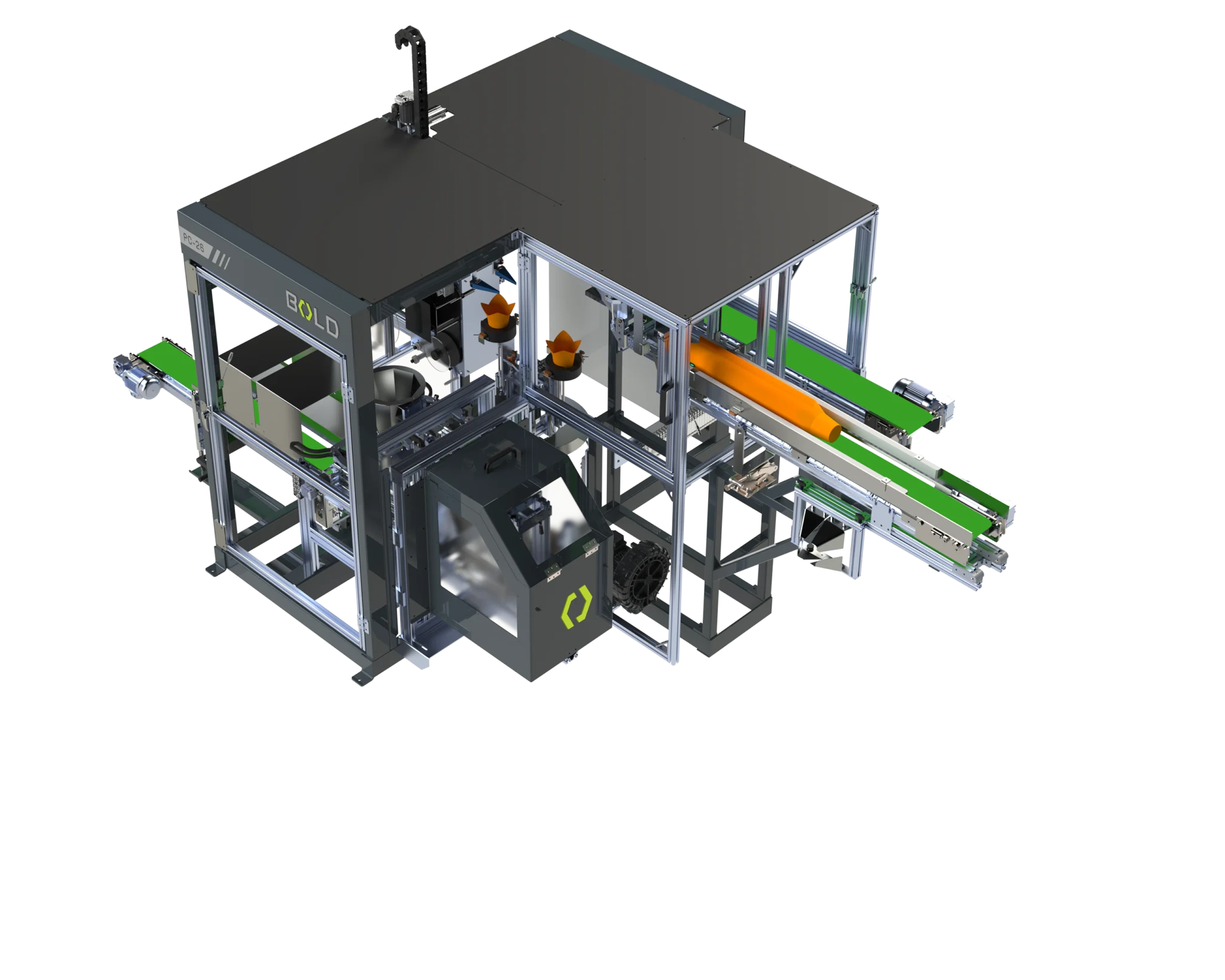

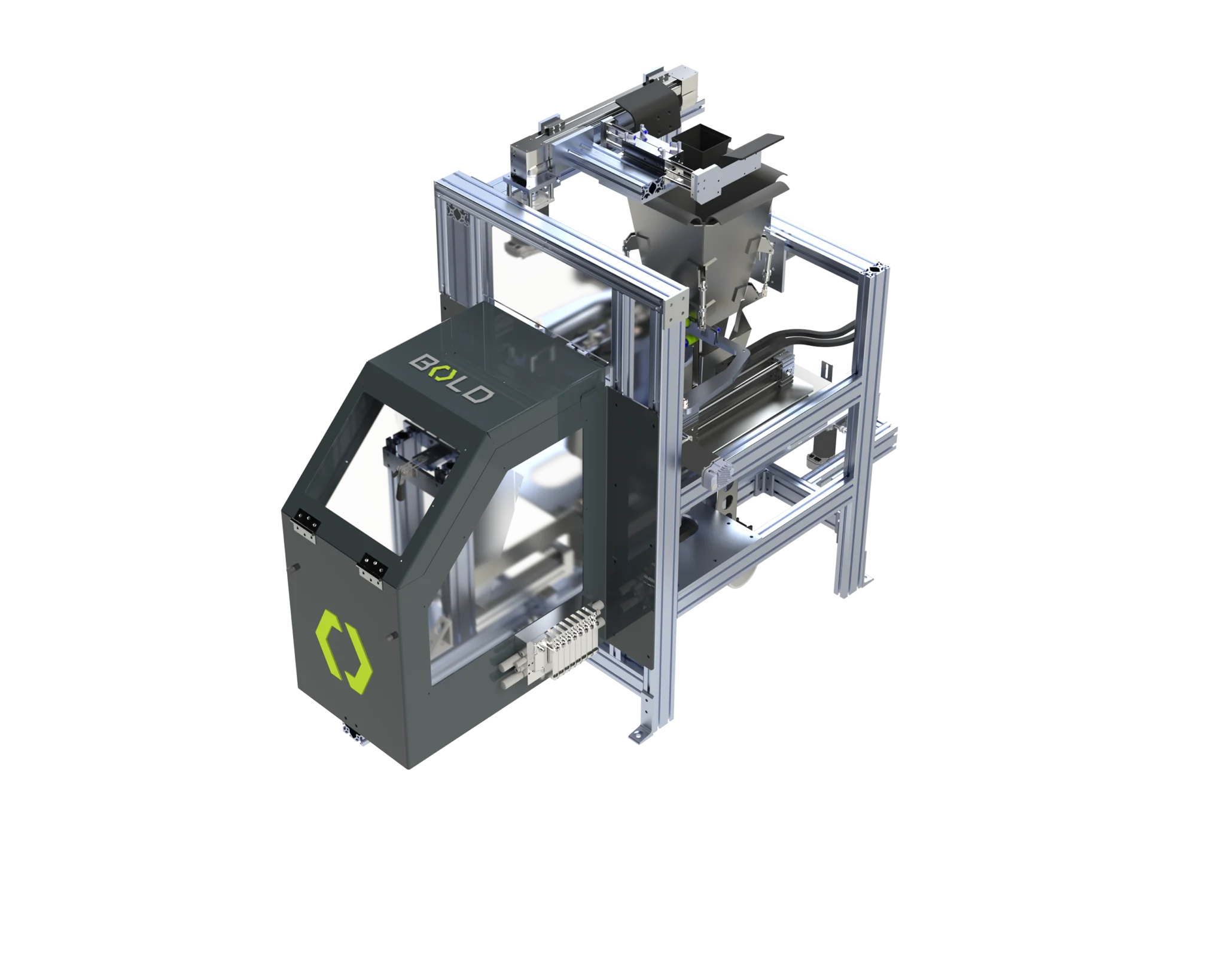

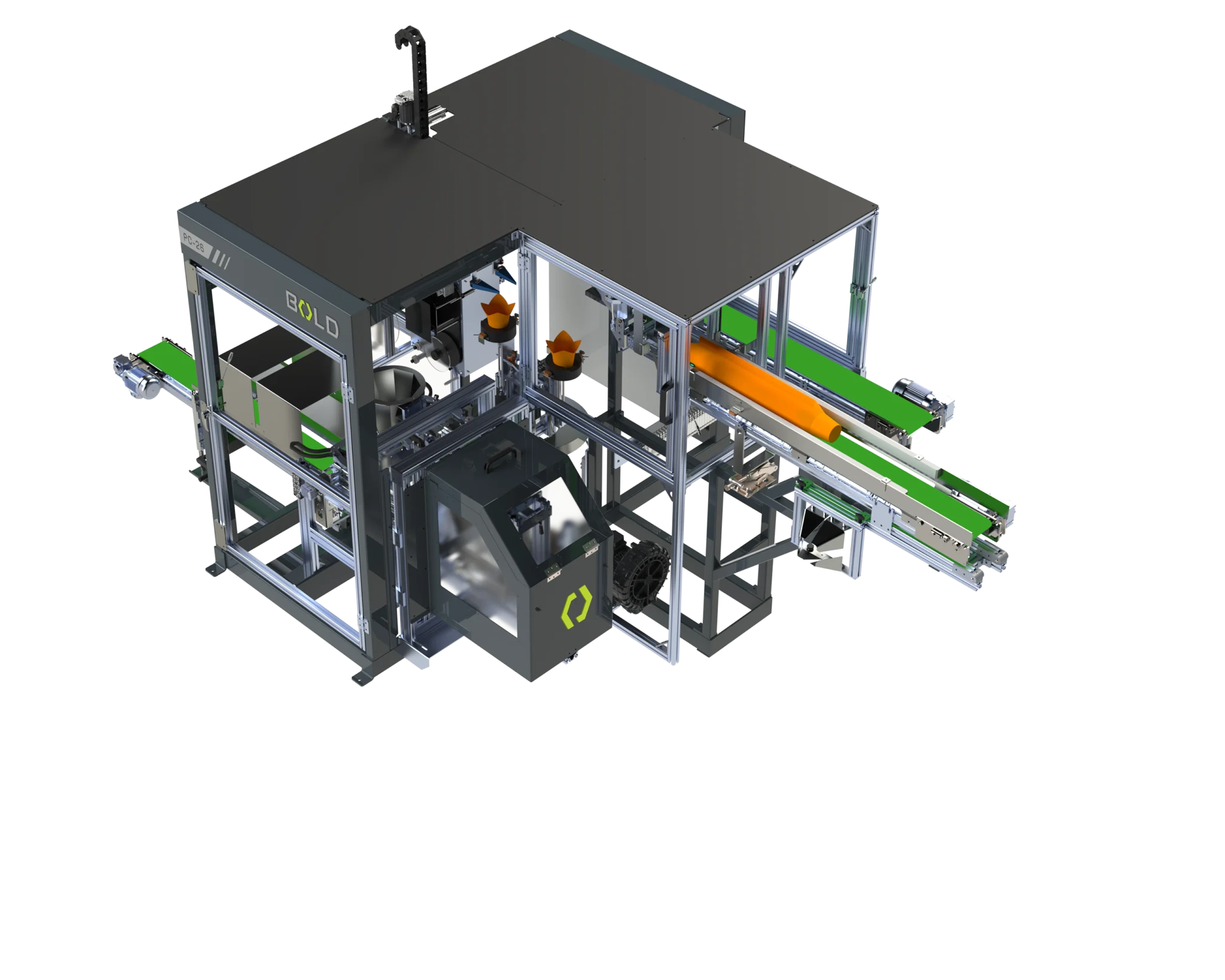

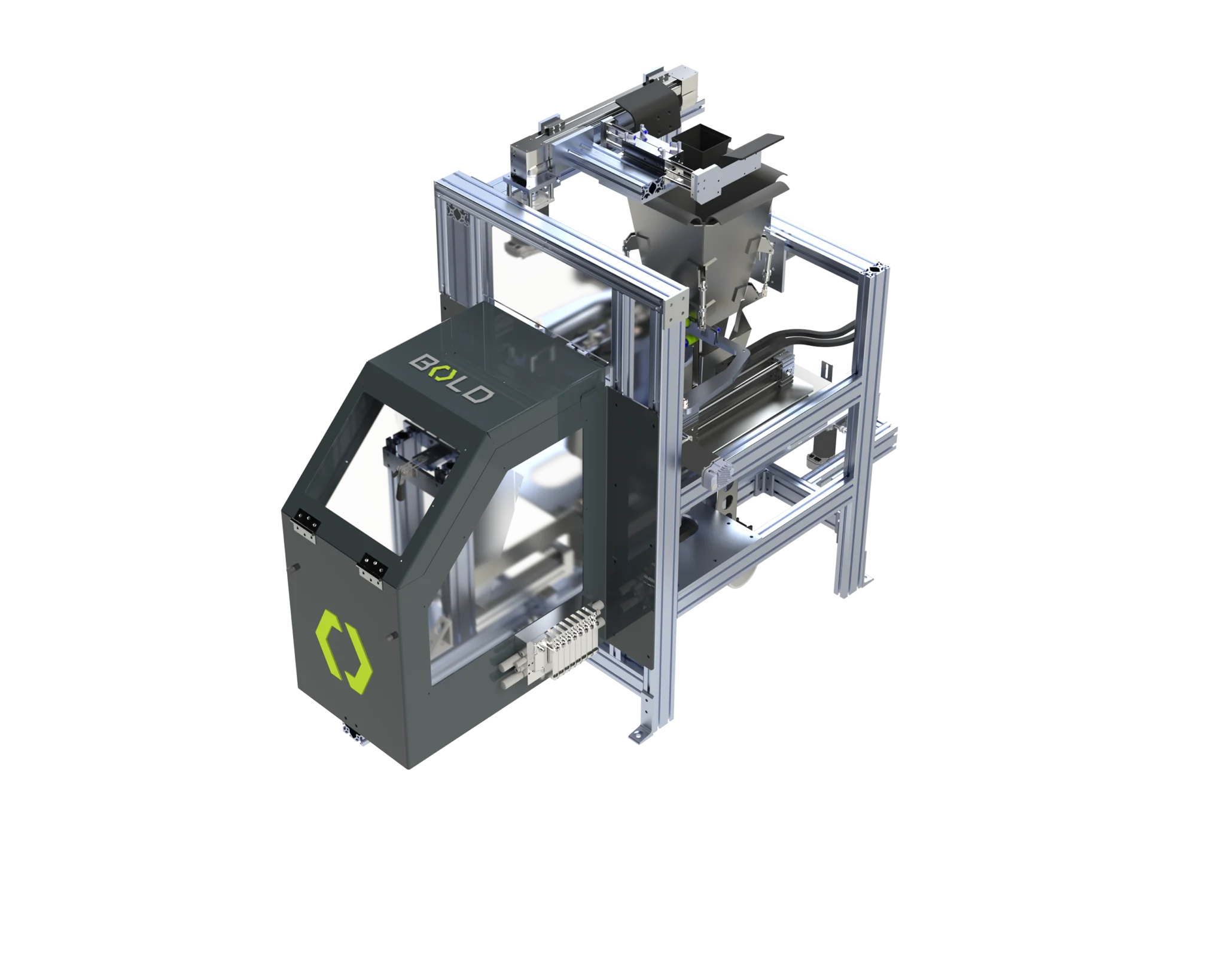

PC-26

POT PACKAGING CELL

The PC 26 Pot Packaging Cell automates the repetitive task of plant upgrading with Pot Cover, UPC, and Sleeve. This versatile machine has a production rate of 1000 pcs/hr.

FEATURES

- Applies side and bottom UPC’s

- Reduces human error with Print on Demand Label Applicator

- Flexible – capable of processing 4" and 6" product, with built in recipes specific for each variety.

PC-26

PC-26

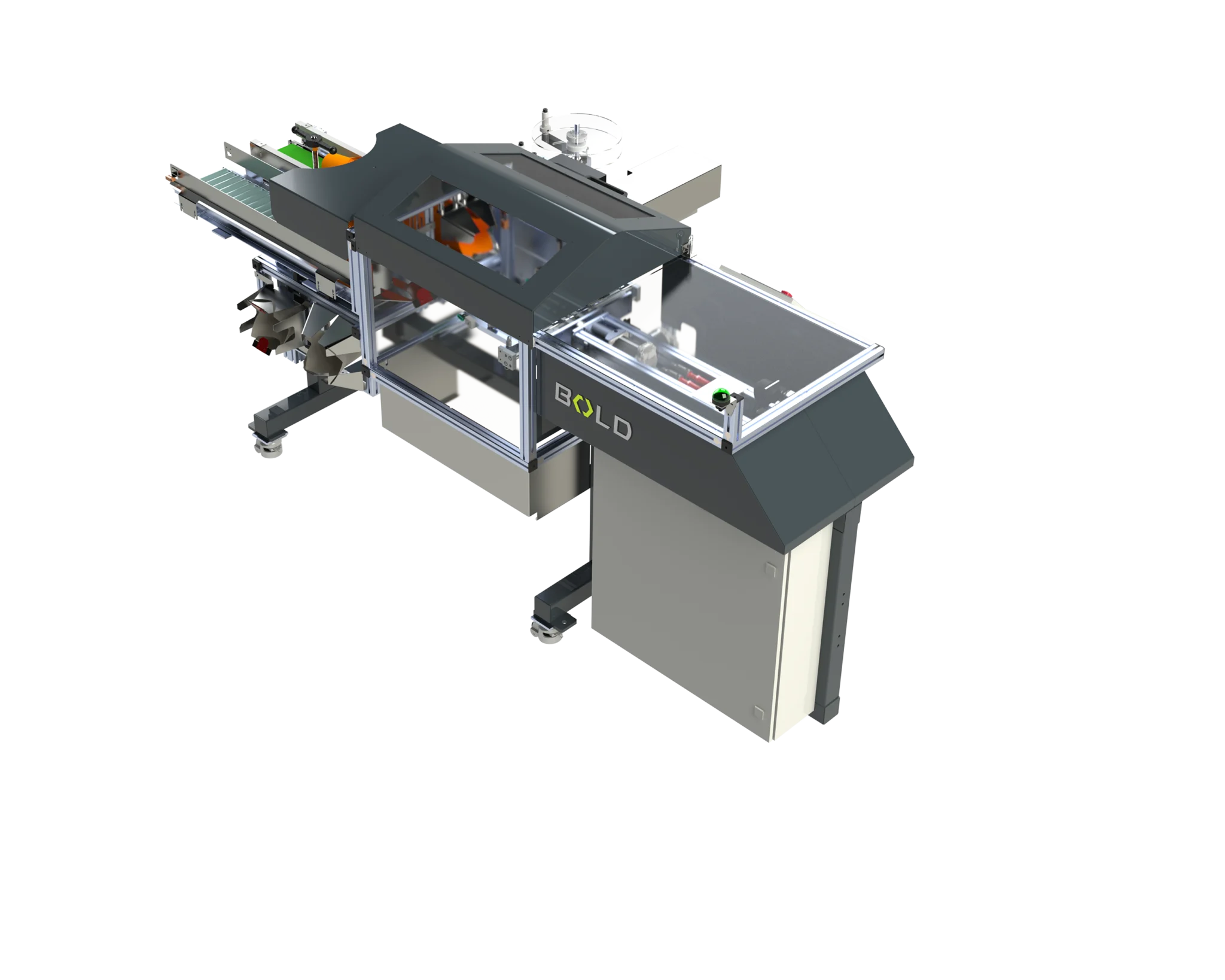

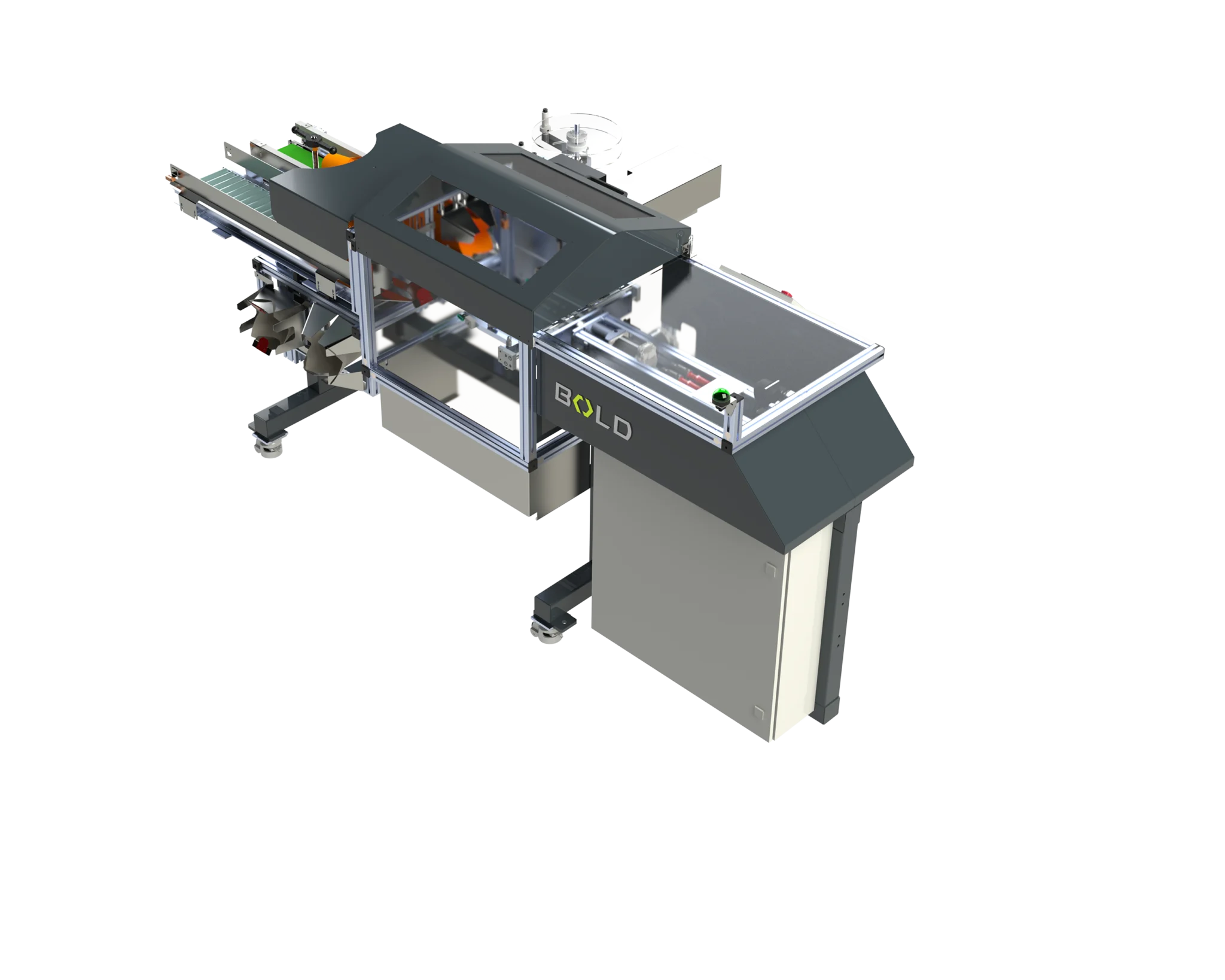

PL-20

UPC MACHINE – SINGLE LEVEL

Our PL-20 automates the monotonous task of applying UPC labels to preformed pot covers. It operates efficiently with a production rate of 1200 pieces per hour. This machine can be outfitted with different upgrades including: conveyor extensions, UPC verification barcode scanner, job barcode scanner, and much more.

FEATURES

- Applies side and bottom UPC’s

- Reduces human error with Print on Demand Label Applicator

- Precise and consistent label placement

PL-20

PL-20

PR-50

POT HANDLING ROBOT

The Bold PR-50 Pot Handling Robot is a versatile machine that can be programmed for use in a variety of different scenarios.

FEATURES

- Plant Spacing and organization

- Plant in/out of Tray

- Plant to/from Rolling Bench

PR-50

PR-50

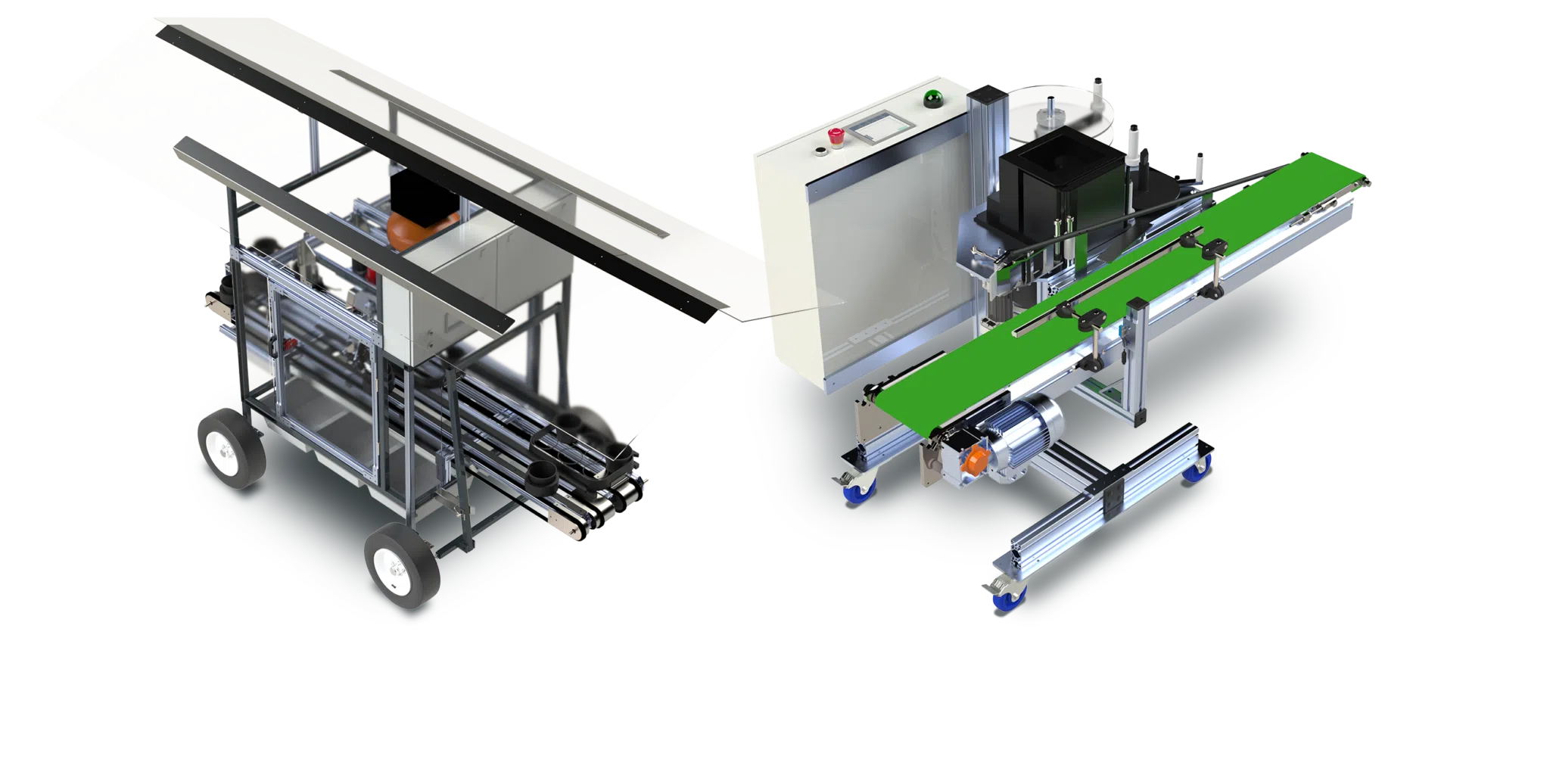

SM-50

SLEEVER

This compact and versatile machine automates the repetitive task of putting the plant into a sleeve. This machine can be used on its own or as part of a larger automation line.

FEATURES

- Consistent, reliable and compact

- Flexible use – utilization in a larger automated solution, or semi-automatic arrangement.

SM-50

SM-50

TM-67

TRANSPLANTER

Introducing innovative Planting with the TM-67 Transplanter. This machine automates the insertion of plugs into larger pots, handling 1200-1500 plugs per hour.

FEATURES

- Small footprint compared to industry standard

- Additional Option: Increase capacity by handling two plugs simultaneously

TM-67

TM-67

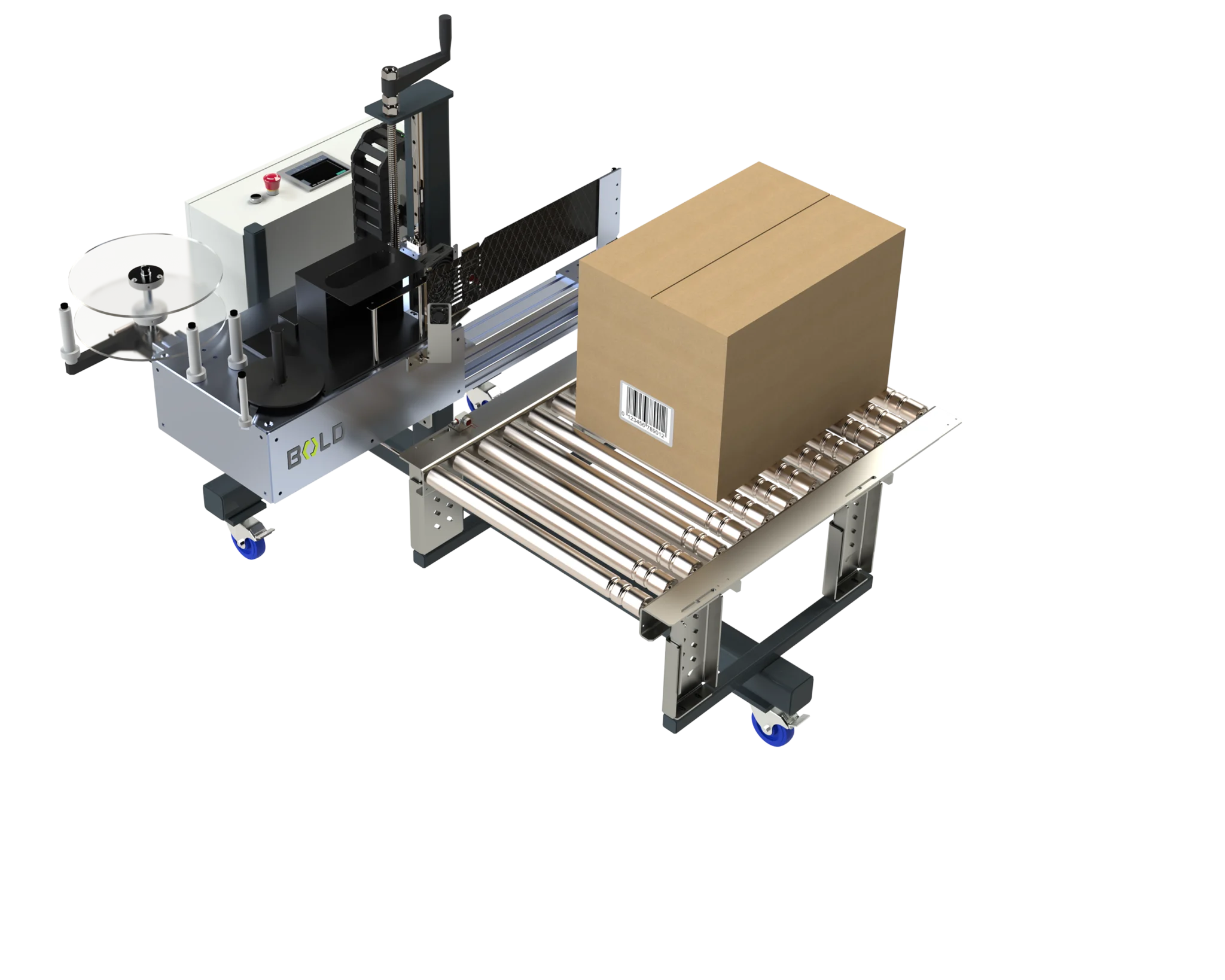

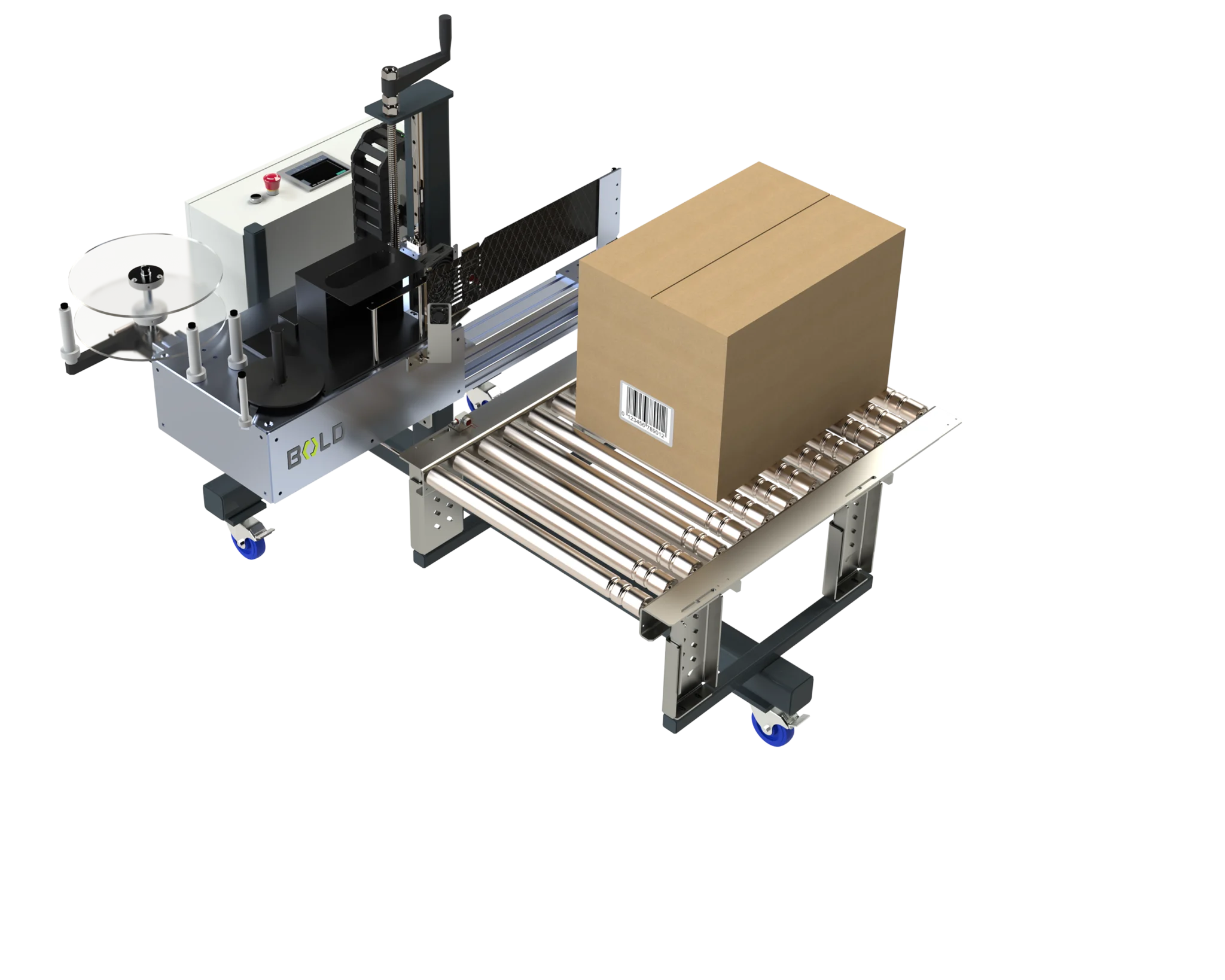

CL-26

CASE LABELER

The CL-26 Case Labeler is a simple solution that is portable and eliminates the potential for human error. This machine is easily integrated into any automation line.

FEATURES

- Consistent label placement

- Job Barcode Scanner

- UPC Barcode verification scanner

- Optional colour printer

CL-26

CL-26

LET’S MOVE FORWARD >>

SEARCHING FOR AN AUTOMATION SOLUTION UNIQUE TO YOUR SITUATION?

LET’S MOVE FORWARD >>

LET’S MOVE FORWARD >>

PC-26

POT PACKAGING CELL

The PC 26 Pot Packaging Cell automates the repetitive task of plant upgrading with Pot Cover, UPC, and Sleeve. This versatile machine has a production rate of 1000 pcs/hr.

FEATURES

- Applies side and bottom UPC’s

- Reduces human error with Print on Demand Label Applicator

- Flexible – capable of processing 4" and 6" product, with built in recipes specific for each variety.

PC-26

PC-26

PL-20

UPC MACHINE – SINGLE LEVEL

Our PL-20 automates the monotonous task of applying UPC labels to preformed pot covers. It operates efficiently with a production rate of 1200 pieces per hour. This machine can be outfitted with different upgrades including: conveyor extensions, UPC verification barcode scanner, job barcode scanner, and much more.

FEATURES

- Applies side and bottom UPC’s

- Reduces human error with Print on Demand Label Applicator

- Precise and consistent label placement

PL-20

PL-20

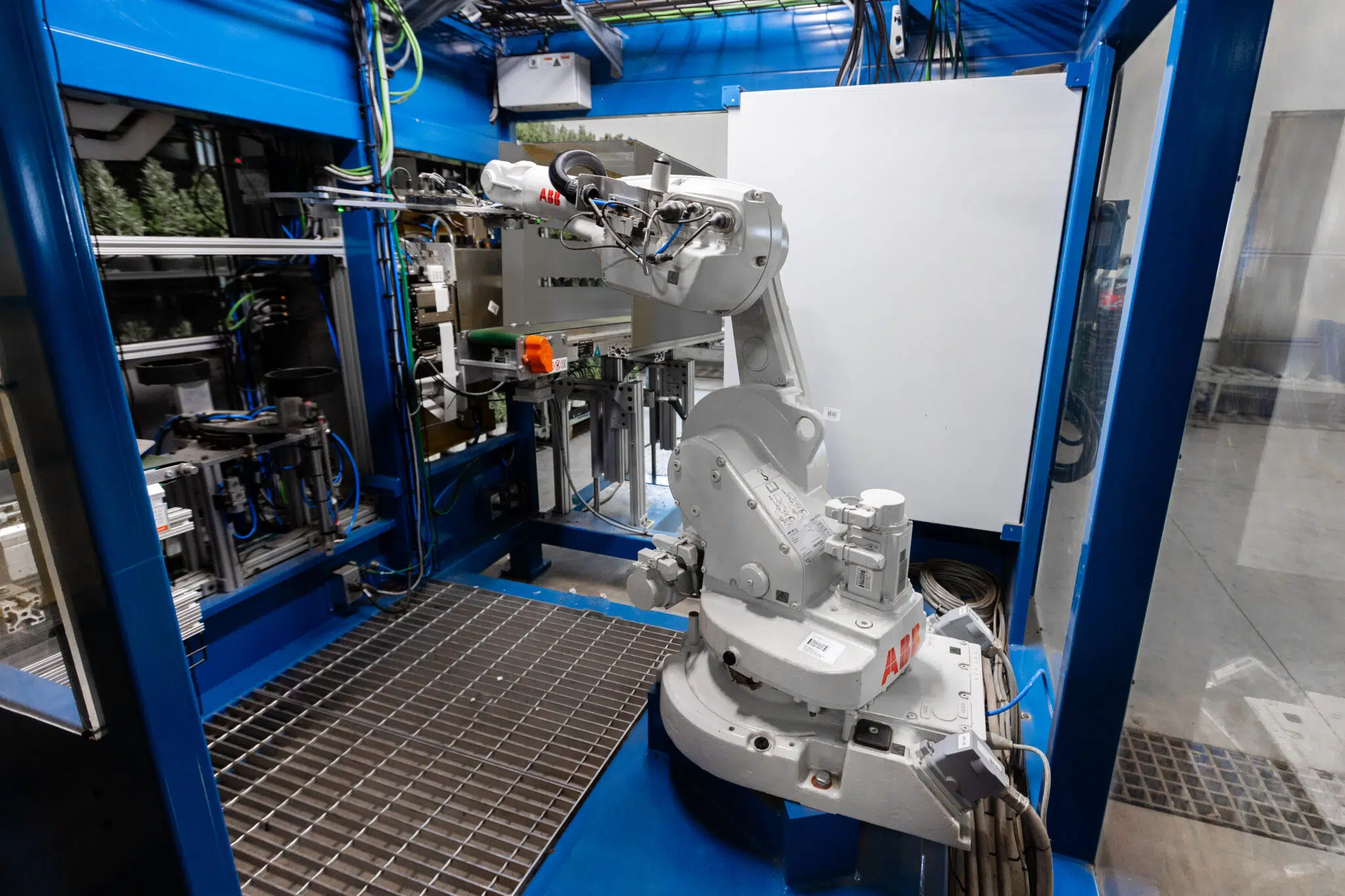

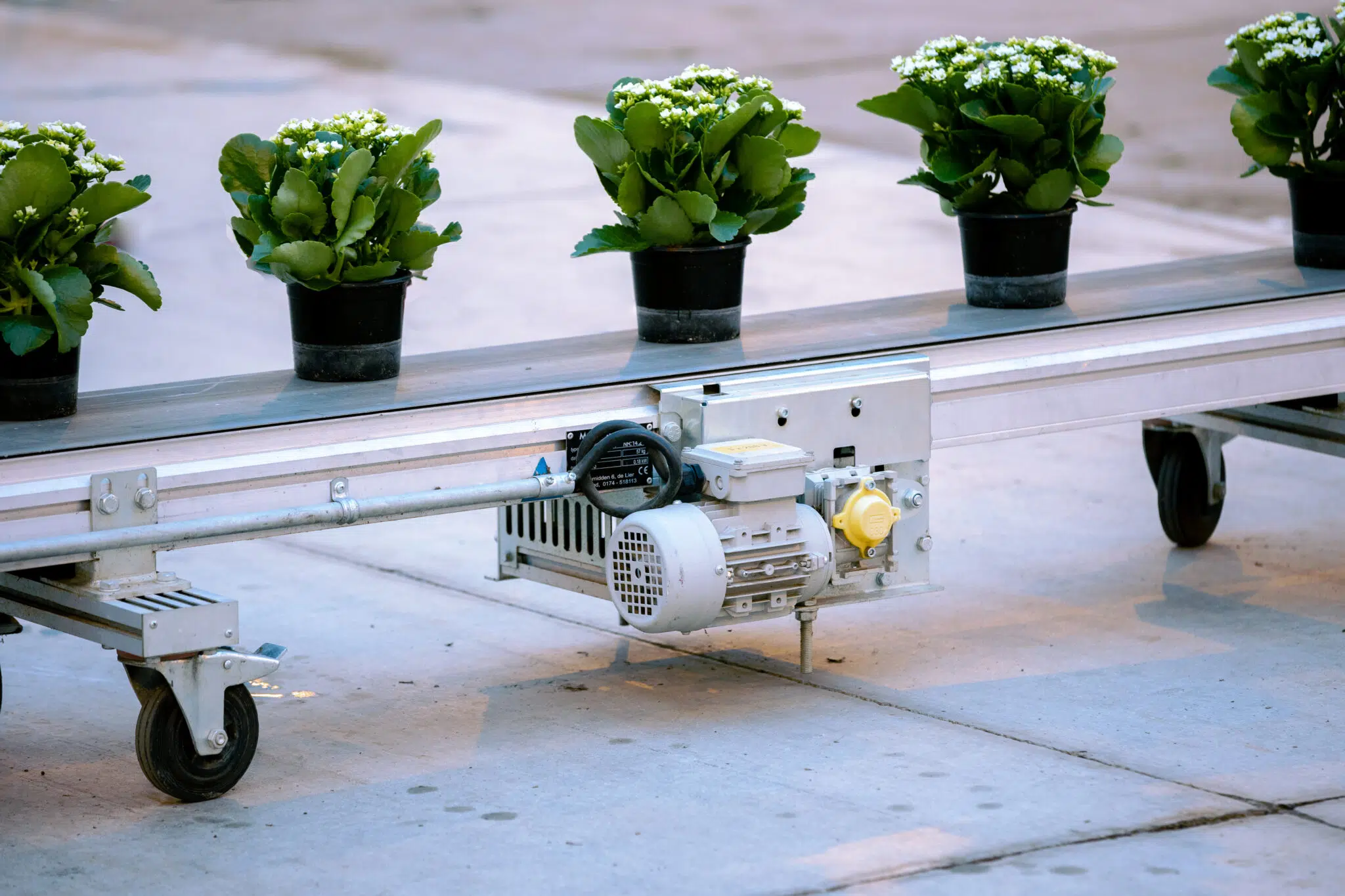

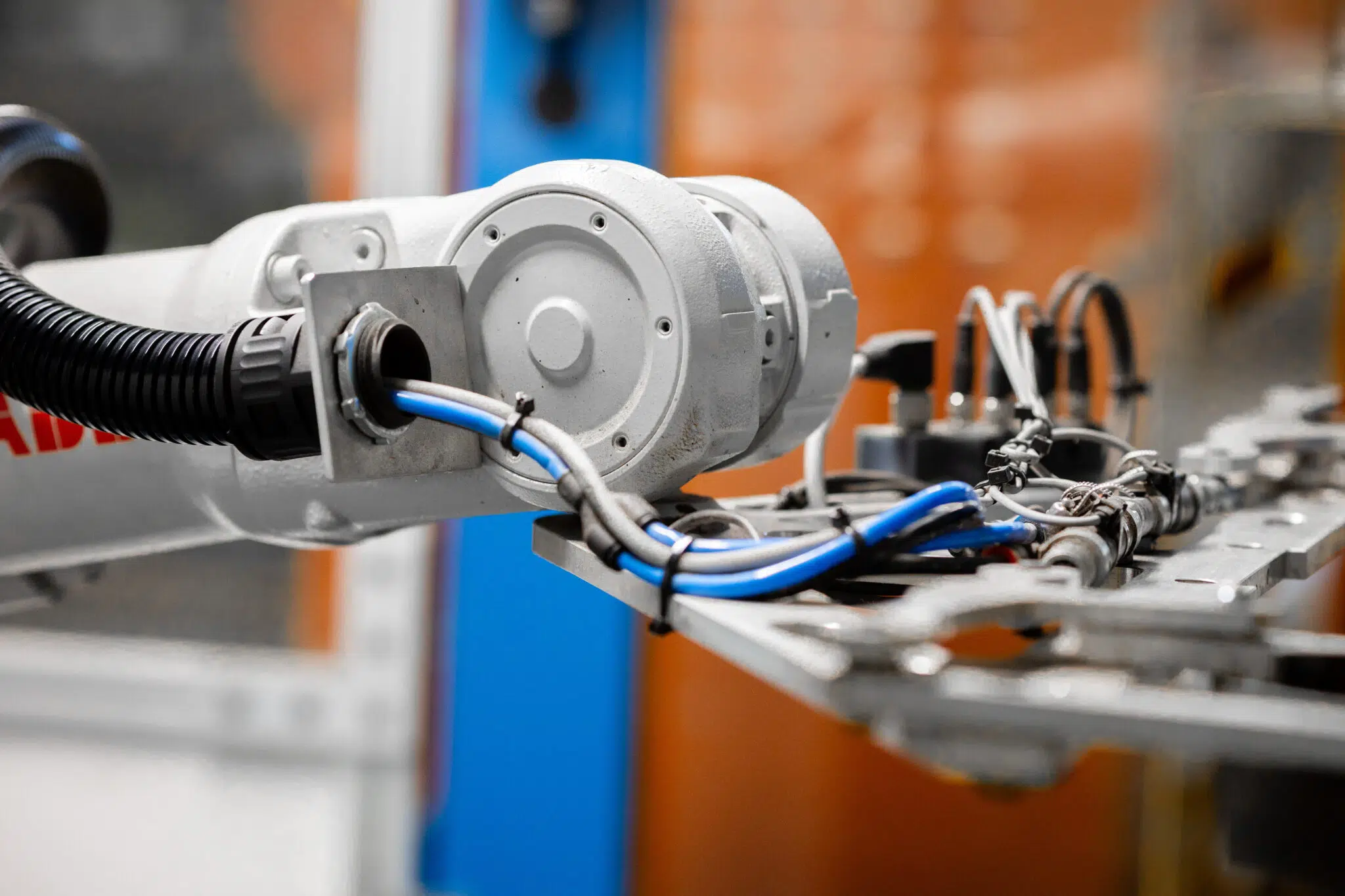

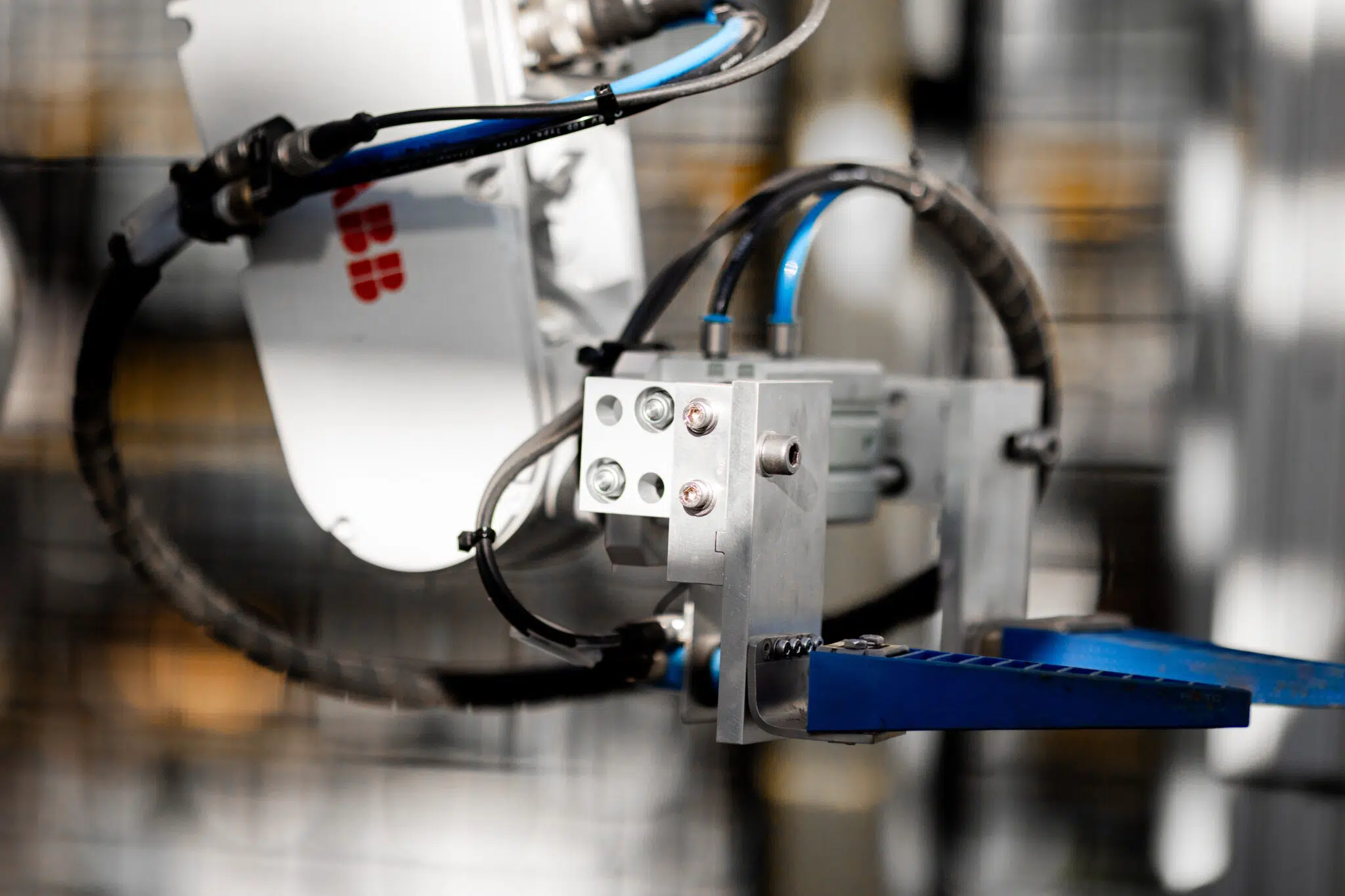

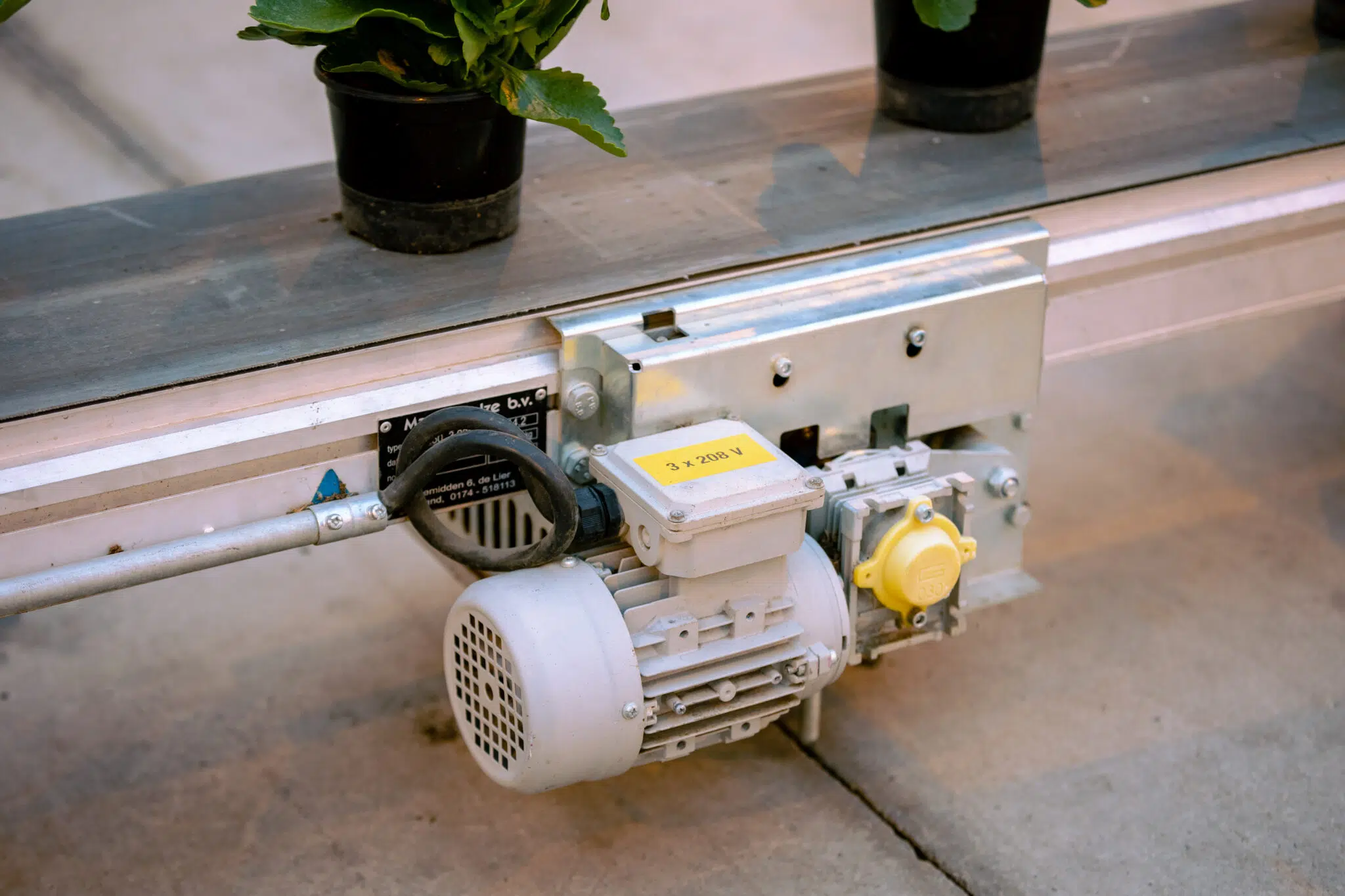

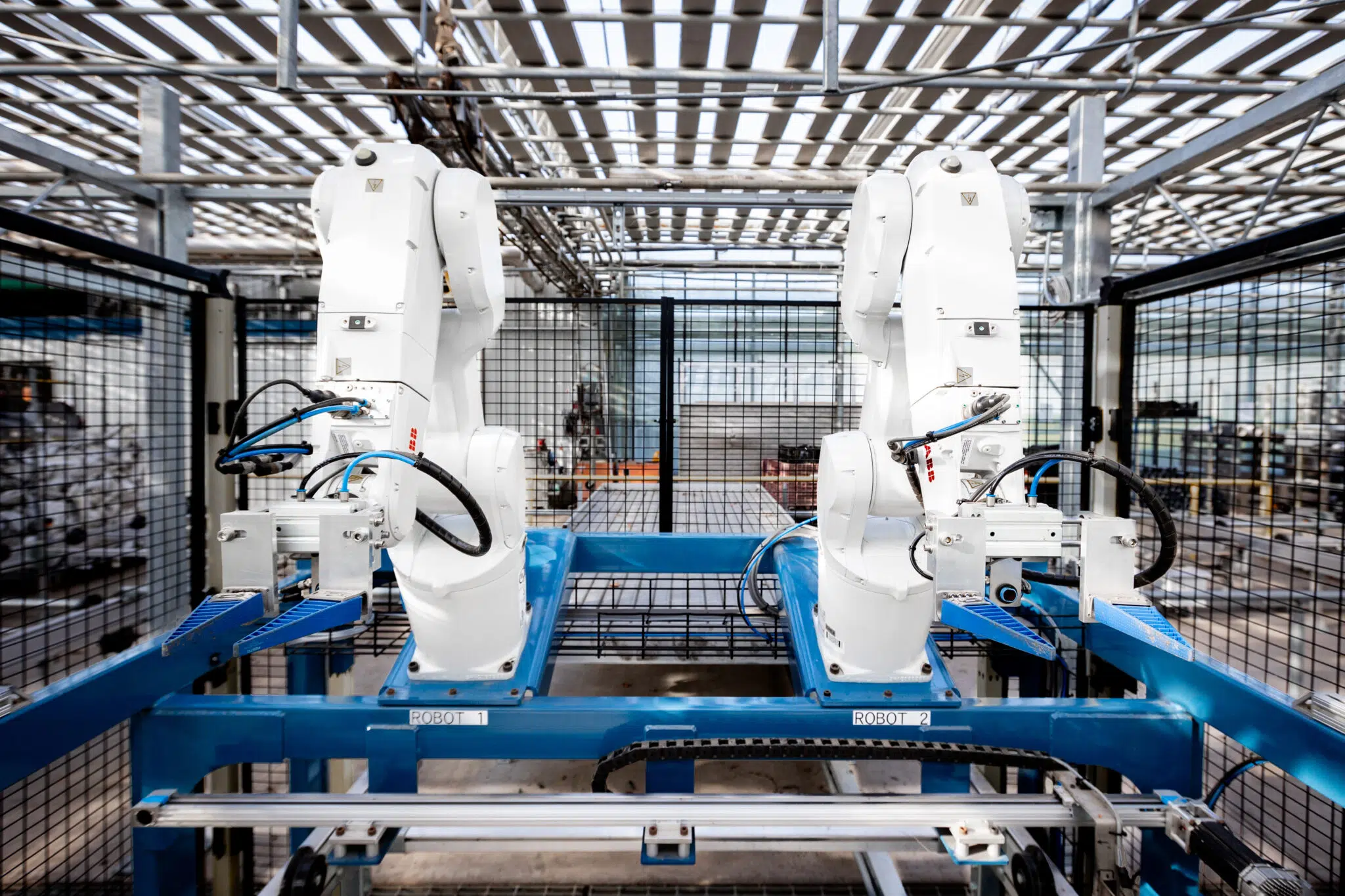

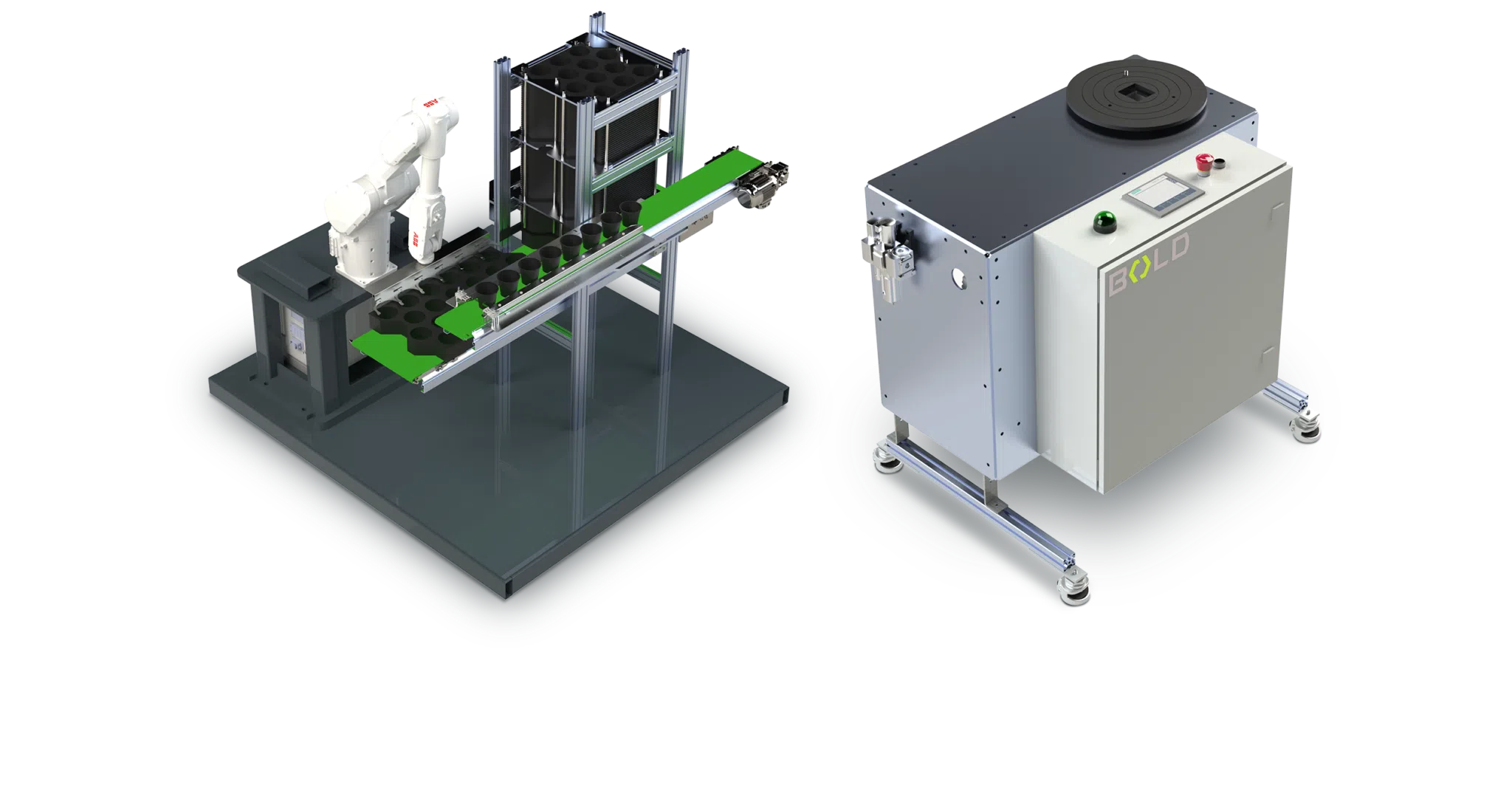

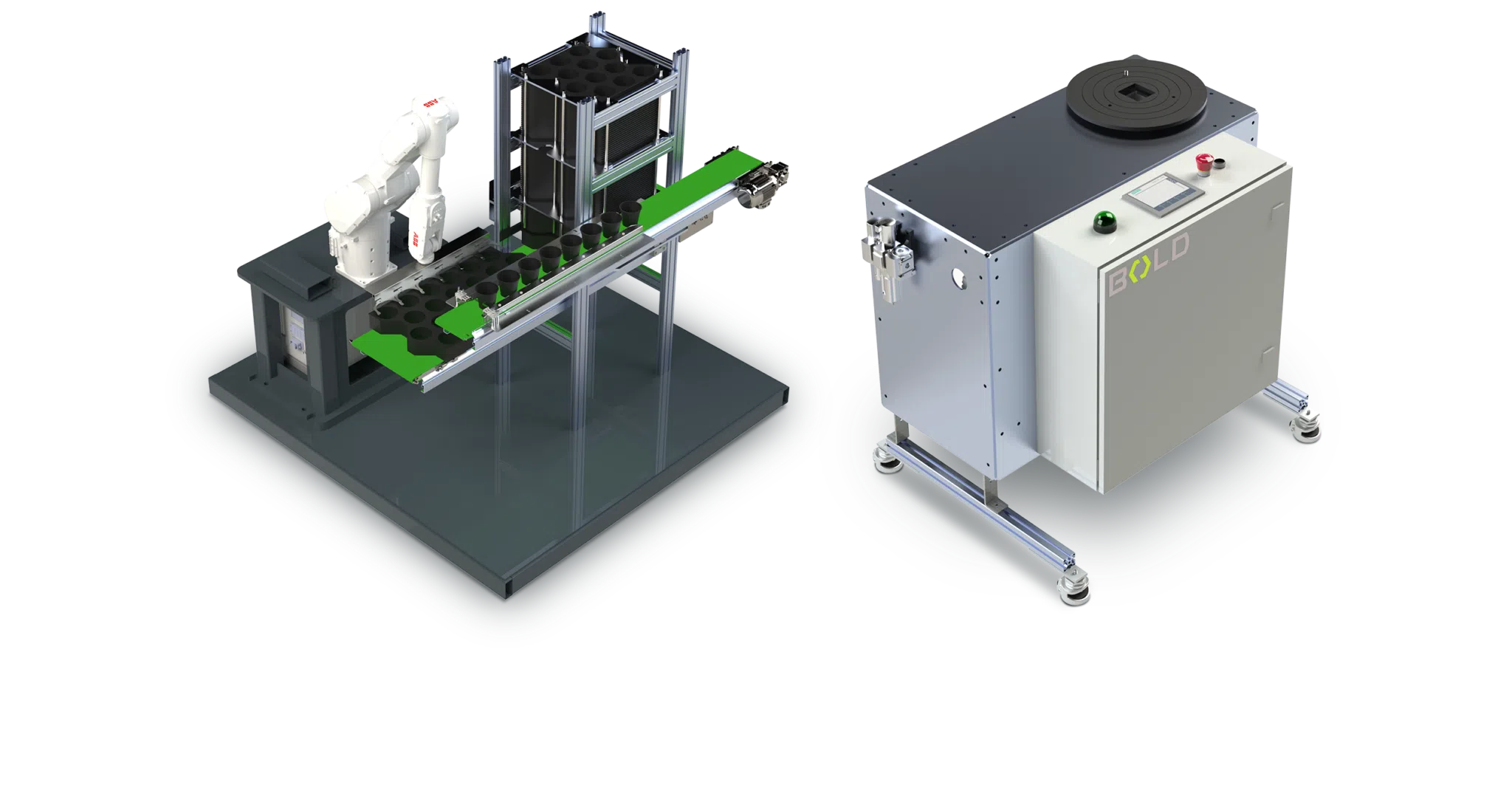

PR-50

POT HANDLING ROBOT

The Bold PR-50 Pot Handling Robot is a versatile machine that can be programmed for use in a variety of different scenarios.

FEATURES

- Plant Spacing and organization

- Plant in/out of Tray

- Plant to/from Rolling Bench

PR-50

PR-50

SM-50

SLEEVER

This compact and versatile machine automates the repetitive task of putting the plant into a sleeve. This machine can be used on its own or as part of a larger automation line.

FEATURES

- Consistent, reliable and compact

- Flexible use – utilization in a larger automated solution, or semi-automatic arrangement.

SM-50

SM-50

TM-67

TRANSPLANTER

Introducing innovative Planting with the TM-67 Transplanter. This machine automates the insertion of plugs into larger pots, handling 1200-1500 plugs per hour.

FEATURES

- Small footprint compared to industry standard

- Additional Option: Increase capacity by handling two plugs simultaneously

TM-67

TM-67

CL-26

CASE LABELER

The CL-26 Case Labeler is a simple solution that is portable and eliminates the potential for human error. This machine is easily integrated into any automation line.

FEATURES

- Consistent label placement

- Job Barcode Scanner

- UPC Barcode verification scanner

- Optional colour printer

CL-26

CL-26

01 // ABOUT US

“

04 // Founders

FOUNDERS

WILLEM BIJLSMA

General Manager and Director of Automation

Willem is an experienced automation professional with a strong agricultural background. Beginning his career in 2009, Willam found his calling in electrical design, software development, and management. He is a co-founder of Bold Robotics contributing significantly to the greenhouse industry with his creativity and problem-solving abilities. Outside work, he enjoys soccer, surfing, and hiking with his family.

BILL VANDENOEVER

Director of Engineering and Sales

Bill is a Mechanical Engineer with a diverse skill set in product development, customer relations, sales, and engineering. Beginning his career in 2006 as a mechanical designer, he advanced to become a Mechanical Engineering Manager, gaining skills in project management, sales, and machine building. In 2017, he co-founded Bold Robotics alongside his business partner Willem. Outside work, Bill enjoys family time, cooking, music, brewing beer, making maple syrup, and tending to his hobby farm.

06 // CONTACT US

GET IN TOUCH WITH BOLD.

OFFICE NUMBER:

EMAIL:

ADDRESS: